Wireless USB Adapter Configuration User Guide

January 11, 2019

Raspberry Pi USB Webcam User guide

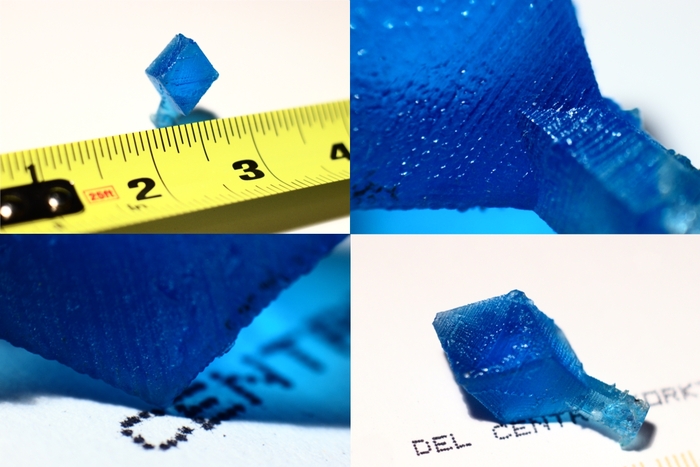

January 11, 2019One week has passed since we updated previous news information about FlameStower . Actually today we will introduce you a super surprizing and astonishing 3D printer. As it is known that 3D printer has achieved increasingly tremendous advancement in technology, but because of high cost, 3D printer has’t been able to emerge in the common household and become the popular necessity for the normal people. But now, the peachy 3D printer has decently solved the problem with the retail price of only $100. Affordable, small, lightweight, and unique, it is praised as the genuinely first household 3D printer. Even though the low cost and lightweight, which is originally their most outstanding advantage, but limited to the small volume, this printer can only make the production with small dimension until now. What’s more, their description informed us of the high speed in printing, but we did’t see any introduction about the production precision. Seen from the demonstrated picture, we have reason to believe that they need to improve it. But anyway, closely abide by the open spirit, they use and add resin to make the world’s most affordable 3D printer, really starting the price innovation in 3D printer, which marked the remarkable step in 3D printer research and development.

How does the Peachy Printer work?

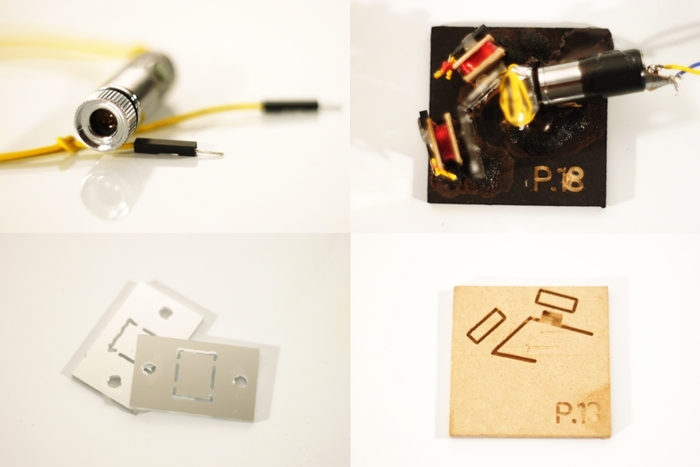

Below is a detailed video explaining how the Peachy Printer works through explanation and demonstration! http://youtu.be/80HsW4HmUes The peachy printer is a Photolithographic printer. That means it uses a controlled beam of light to cure light sensitive resin into hard objects. The peachy moves a laser beam along the X and Y axes to create the shape of the object, while using a drip system to control the level of the resin on the Z axis which determines the height of the object.